|

| Hindustan Radiators and Heat Exchangers Pvt. Ltd. puts great emphasis on quality. It’s ultimate aim is to adopt total quality approach as per the requirements of ISO-9001:2008. The quality policy of the company is stated in the following words. “The objective of Hindustan Radiators and Heat Exchangers Pvt. Ltd. is to deliver to customers only quality products which meet their requirements and are to their entire satisfaction”. The company strives for continuous improvement in its products by application of new emerging technologies. |

|

The Quality Department, working under the above philosophy, has been assigned the following responsibilities. |

1. Inspection of raw materials.

2. Inspection at different stipulated stages of manufacturing.

3.

Laying down testing procedures and assisting external inspection agencies.

4. Prescribing and maintaining quality documents. |

Inspectors from External Agencies are appointed by the customer, including third party inspectors like RITES, LLOYDS, PDIL, EIL, BVIS, ABS, VELLOCI etc.

Whenever a job is taken in hand, a Quality Plan is worked out and if desired, it is sent to the customer for comments and approval. The customer is welcome to inspect the quality at any stage of manufacture. The quality plan indicates the various checks and tests to be conducted at different stages of manufacturing. |

|

| |

|

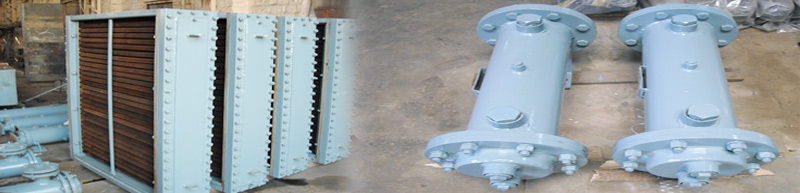

The Group has expertise of designing all types of Heat Exchangers as per national and international standards including IS, TEMA, ASME,API, BS, DIN, GOST, JIS, AND IBR etc and any other standard specified by the customers. Design department initiates and supervises the required R & D work. A state of art Computer - Aided Design (CAD) facility has been installed for designing and drafting of Heat Exchangers. |

|

|

|

We have both pneumatic and hydraulic pressure testing setup for all heat transfer equipment manufactured by us.The range of pneumatic testing is upto 20 bar and hydraulic testing upto 100 bar. In addition we have all measuring instruments for accurate dimensional check. |

|

| |

| B) Testing Facilities Arranged From Outside

Sources |

| Radiography test (X Rays Test) |

| Normalizing of welding joints |

| Testing of Material |

|

Chemical Composition Test |

|

Elongation Test |

|

Hardness Test |

|

Impact Test |

| Ultrasonic Test |

| Eddy Current Test |

|

| |